|

Schaeffler the axlebox bearings in the Velaro CRH3 for China

6. Nov, 2010 SHANDONG OBETTER BEARING CO., LTD

(FAG INA LUK Schaeffler) In November 2005, the Chinese national railway “China Railways”, acting on behalf of the Ministry of Railways (MOR),ordered sixty 8-car high speed trains from Siemens, Figure 1. This order was followed in March 2009 by an order for components for a further one hundred 16-car trains. For both sets, it was agreed that a proportion of the trains will be produced in Europe, with the remainder being produced in China. The high requirements of the customer for localisation were thus met by a level of technology transfer between Siemens and various Chinese partners.

The high speed train CRH3 was developed on the basis of the multiple unit technology in the Velaro platform from Siemens that is already in use by Deutsche Bahn AG and the Spanish railway operator RENFE as well as the Russian state railway company RZD. The first set of trains was designed for a speed of 300 km/h, while the following expansion set will achieve 350 km/h. With a total length of approx. 200 m, the 8-car multiple units are 315 mm wider than the European variants despite running on a standard gauge track (total width: 3 265 mm).

They can accommodate 601 passengers and technical measures were taken to adapt them to high speed travel within the People’s Republic of China. One week before the start of the Summer Olympic Games in August 2008, the first 8-car trains began travelling on the Beijing-Tianjin high speed route. Since December 2009, they have been travelling the 1068 km long Wuhan- Guangdong route. The one hundred 16-car trains are intended to operate on the 1318 km long route between

Beijing and Shanghai.

Technical data for CRH3:

■ Wheel arrangement

– Bo´Bo´

■ Unladen weight

– 447t

■ Axle weight

– 17,7 t

■ Maximum speed

– Operation: 300 km/h

– Expansion stage: 350 km/h

■ Power rating (8-car CRH3)

– 8,8MW.

Axlebox bearings

The Siemens bogie design is based on the Velaro platform, in which a swing arm solution is provided for the axlebox bearing. The complete swing arm developed

by Schaeffler Group Industrial comprises a split housing unit consisting of an upper and lower section as well as the rolling bearing. This facilitates easy dismounting of the wheelsets.

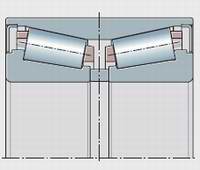

Rolling Bearing

The double row tapered roller bearing unit TAROL is a complete unit comprising the base bearing and the sealing elements. The bearing, which is filled with the correct grease quantity for a service interval of 1,2 million km and sealed by sheet metal covers, is designed for the relevant operating conditions and is Manufactured in Accordance with EN 12080. Initial mounting is carried out at

Siemens TS in Graz. In order to ensure correct mounting, the Siemens mounting personnel are specially trained by the Industrial Aftermarket Service of the Schaeffler Group. The Siemens axlebox bearing mounting facility is certified by Industrial Aftermarket Service and is thus authorised to mount FAG axlebox bearings.

Axlebox bearing housings

The material of the axlebox bearing housing is a spheroidal graphite cast iron to EN-GJS-400-18-LT. The strength of the housing unit was calculated and optimised with the aid of the Finite Element Method. In the design of the housing unit, the particular requirements associated with the extremely high speed were taken into consideration,

Bogie

In the CRH3, the cars are fitted alternately with motor bogies and unpowered bogies. This uniform distribution of the underfloor drive units over the whole length of the train gives more effective acceleration.

Due to the uniform weight distribution over the whole multiple unit, the weight acting on the individual wheelset is reduced. This helps to reduce the impact on the railtracks and the maintenance requirements for the running gear.

Due to this drive concept, it is also possible to negotiate steeper sections

of track with a gradient of up to 40‰.

Shandong Obetter bearing Company is a leading global supplier in the areas of bearings, mechatronics, services. OBT Group as a high-tech enterprise and professional manufacturer specicalized in ball bearing and roller bearing. we can produce non-standard bearing and machine parts as our customers request. we always follows the principles of "Good Faith, Equality, Cooperation and Win-Win" to cooperate with our customers.

For additional information, please contact:

Company brand: OBT Bearing

Company Name: Shandong Obetter Bearing Co., Ltd

WebSite: www.obtbearing.com

Tel/FAX:86-635-8511972

E-mail: obtbearing@163.com |